Are you tired of uneven patches and bumps ruining the look of your lawn? A lawn roller can be the secret weapon you need to get that smooth, professional finish right in your own yard.

But why spend money on expensive equipment when you can build your own DIY lawn roller with simple materials? Whether you’re preparing a new lawn, pressing down freshly laid grass seed, or just want to keep your turf looking flawless, making your own lawn roller is easier than you think.

In this guide, you’ll discover step-by-step instructions, smart tips, and practical ideas to create a reliable roller that fits your needs. Keep reading, and soon you’ll be rolling your way to a perfect lawn that neighbors will envy.

Materials Needed

Building a DIY lawn roller requires gathering the right materials. Each part plays a key role in making the roller strong and easy to use. Choosing good materials saves time and effort during assembly. This guide lists the common supplies needed for most designs.

Axle Options

The axle holds the roller and allows it to spin smoothly. Steel pipe is a popular choice for strength and durability. Solid metal rods also work well for smaller rollers. Select an axle size that fits your roller’s width and weight.

End Caps And Fittings

End caps close the roller’s tube and keep filler material inside. Plastic or rubber plugs are easy to install and seal well. Wood or metal plates offer a sturdier option. Fittings like pipe reducers help connect the axle securely to the roller ends.

Frame And Handle

The frame supports the axle and provides a place to hold the handle. Metal or wood can be used to build the frame. The handle should be long enough for easy pushing or pulling. A simple T-shaped handle works best for control.

Filler Choices

Filling the roller adds weight for better soil compression. Water is the most common filler because it is easy to fill and drain. Sand or gravel adds more weight but is harder to remove. Choose a filler based on how heavy you want the roller to be.

Essential Tools

Basic tools make building the lawn roller possible. You will need a drill to make holes for the axle and fittings. A wrench or pliers help tighten bolts and fittings. A saw is useful if you need to cut wood or metal pieces. Measuring tape ensures accurate dimensions.

Credit: www.youtube.com

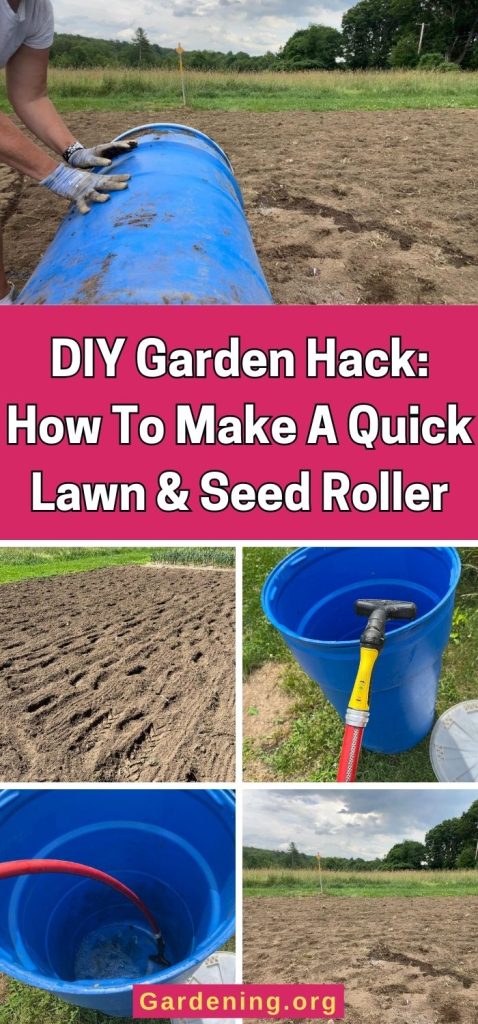

Preparing The Barrel

Preparing the barrel is a key step in building a DIY lawn roller. The barrel acts as the drum that flattens your lawn. It needs to be clean and properly modified to work well. Careful preparation makes the roller effective and easy to use.

Cleaning The Drum

Start by removing any dirt, rust, or old paint from the barrel. Use a wire brush or sandpaper for this task. A clean surface helps the roller work smoothly. Wash the drum with soap and water to clear away dust. Let it dry completely before moving to the next step. This prevents rust and helps paint stick if you choose to paint the barrel.

Drilling Axle Holes

Mark the spots on each side of the barrel where the axle will go. Use a tape measure to keep holes level and centered. Drill holes with a metal drill bit suitable for the barrel’s thickness. Make sure holes are wide enough for the axle to fit without wobbling. Smooth the edges of the holes with a file. This stops sharp edges from cutting the axle or your hands later.

Installing The Axle

Installing the axle is a crucial step in building your DIY lawn roller. The axle holds the roller cylinder and allows it to spin smoothly. A well-installed axle ensures the roller works efficiently and lasts longer.

Use a strong metal rod or steel pipe as the axle. It must fit snugly inside the roller cylinder. Make sure to measure the length carefully to match the roller width.

Sliding The Metal Rod

Start by sliding the metal rod through the center of the roller cylinder. Push it gently but firmly to avoid bending. The rod should extend evenly on both sides of the roller.

Keep the rod straight for better balance. Check for any resistance or tight spots inside the cylinder. These may need light sanding or cleaning.

Securing With Bushings

Place bushings on both ends of the metal rod. Bushings reduce friction and help the roller spin smoothly. They also protect the rod and roller from wear.

Use a tight fit for the bushings to prevent wobbling. Secure them with end caps or washers to lock the rod in place. Ensure the roller moves freely without sticking.

Sealing And Filling

Sealing and filling your DIY lawn roller ensures it works well and lasts long. Proper sealing stops water or filler from leaking. Filling adds weight to press the soil evenly. This section explains how to create end caps, add a filling port, and choose the best filler.

Creating End Caps

End caps close the roller’s open sides tightly. Use strong materials like wood, metal, or thick plastic. Cut the caps to fit the roller’s diameter exactly. Attach them firmly with screws or heavy-duty adhesive. Make sure the caps do not move or leak. Good sealing keeps the filler inside and protects the roller.

Adding A Filling Port

A filling port lets you add or remove filler easily. Drill a hole on one end cap for the port. Use a pipe fitting or a spout that screws on tightly. This port should seal completely to prevent leaks. Place it high enough to avoid spilling when rolling. A secure port makes filling and emptying quick and simple.

Choosing The Filler

Pick a filler that adds enough weight but is easy to handle. Water is common because it is cheap and simple to fill. Sand or gravel works well for heavier rollers. Consider mixing water with antifreeze to prevent freezing in cold weather. Avoid fillers that can damage the roller or are hard to remove later. The right filler improves roller performance and durability.

Building The Frame

Building the frame is a key step in making a DIY lawn roller. The frame holds everything together. It must be strong and stable. Using the right materials and methods ensures the roller works well. Steel pipes or metal rods are common choices. The frame design depends on your roller size and weight.

Start by deciding how to join the frame parts. You can weld or bolt them. Then, add pillow block bearings to allow smooth rolling. Finally, attach a hitch or handle for easy pulling. Each part has a simple role but must fit perfectly.

Welding Or Bolting Frame

Welding joins metal parts permanently. It creates a strong, rigid frame. Use a welding machine and safety gear. Clean the metal surfaces before welding. Weld along all joints for solid strength. This method is best for heavy-duty rollers.

Bolting is easier and needs no special tools. Drill holes in metal parts at connection points. Use bolts, washers, and nuts to fasten pieces. Bolting allows frame disassembly or adjustment. Choose bolts with corrosion resistance for outdoor use. Tighten bolts well to avoid loose joints.

Attaching Pillow Block Bearings

Pillow block bearings support the axle and allow rolling. Choose bearings that fit your axle size. Mount the bearings on the frame sides securely. Use bolts or screws through the bearing flange holes. Align bearings straight to prevent axle wobble. Check that the axle spins freely inside bearings.

Adding Hitch Or Handle

The hitch or handle lets you pull the roller easily. Weld or bolt a metal tube or rod to the frame front. The length should suit your height and pulling method. Add a grip or handle at the end for comfort. Make sure the hitch is strong and stable. Test by pulling the frame before filling the roller.

Credit: gardening.org

Finishing Touches

Adding the finishing touches to your DIY lawn roller ensures it lasts longer and works better. These final steps improve both the look and function of your roller. Small details make a big difference in the end result.

Take your time with these last steps. They help protect the roller from weather and wear. Also, a thorough check of all parts keeps the roller safe to use and stable during work.

Painting The Frame

Painting the frame protects it from rust and damage. Use a rust-resistant paint suitable for metal surfaces. Choose a color that blends well with your garden tools or stands out for easy spotting.

Clean the frame before painting. Remove dirt, grease, or old paint flakes. Use a primer for better paint adhesion and longer life. Apply two thin coats rather than one thick coat for a smooth finish.

Final Assembly Check

Check every bolt, nut, and connection for tightness. Loose parts can cause wobbling or damage during use. Make sure the roller spins smoothly without sticking or wobbling.

Test the handle for comfort and control. Adjust or tighten any parts that feel weak or loose. This step helps ensure your DIY lawn roller works safely and efficiently.

Weight And Durability Tips

Choosing the right weight and ensuring durability are key factors in making a DIY lawn roller effective. Proper weight helps flatten soil evenly without damaging the grass. Durability ensures your roller lasts through many uses and seasons. Focus on weight options that suit your lawn size and soil type. Select strong materials for the frame and drum to withstand regular wear. These tips make your lawn roller practical and long-lasting.

Weight Options Explained

Lawn rollers come in different weights. Light rollers are easier to move but may not press soil well. Heavy rollers flatten soil better but require more effort to push or pull. Some DIY rollers use water or sand to adjust weight. Filling the drum allows you to control pressure on the lawn. Empty rollers are simple to store and carry. Choose weight based on lawn size and soil condition.

Frame And Drum Longevity

The frame and drum must resist rust and damage. Use steel or thick metal pipes for the frame. Weld or bolt parts firmly for extra strength. Paint metal surfaces to prevent rust. For the drum, strong metal or plastic barrels work well. Avoid thin or weak materials that dent easily. Check joints and bearings regularly to keep the roller rolling smoothly.

Alternative Roller Ideas

DIY lawn rollers can be made from many materials. Choosing the right roller helps smooth your lawn without spending much money. Alternative roller ideas use common household items. These options work well for light lawn rolling tasks. They also save time and effort while preparing your garden.

Using Carpet Or Broom

Old carpet pieces make simple lawn rollers. Cut a carpet strip and roll it tightly. Secure it with strong tape or rope. Drag the carpet roll over the lawn to press soil and seeds.

A broom can also serve as a light roller. Use a wide push broom with stiff bristles. Push the broom gently over the lawn surface. It flattens small bumps and helps seeds settle.

Other Diy Roller Materials

Empty plastic barrels or large cans work well as rollers. Fill them with water or sand for weight. Attach a sturdy handle or pipe through the center. Roll slowly to avoid soil damage.

Concrete blocks or bricks can also press the lawn. Wrap them in a cloth to protect grass. Move them carefully over the area needing leveling.

These DIY materials provide affordable and effective lawn rolling. Choose the option that fits your tools and lawn size.

Rolling Techniques

Rolling your lawn helps create a smooth, even surface. It improves soil contact and compacts the ground gently. Using the right rolling techniques protects your grass and soil. It also helps lawn seed settle well. Follow simple steps for effective and safe rolling.

Proper Lawn Rolling Method

Start rolling when the soil is moist but not wet. Roll in one direction first, then go perpendicular. Use slow, steady movements to avoid soil damage. Avoid rolling when the ground is too hard or dry. This can cause soil compaction and harm roots. Light pressure works best for most lawns. Heavy rolling can crush grass and soil structure.

Roll over bumps and uneven spots carefully. Repeat rolling if needed but never overdo it. Keep the roller clean to prevent spreading weeds or disease. After rolling, water the lawn lightly to help grass recover.

Avoiding Seed Displacement

Roll grass seed right after spreading it to press seeds into the soil. Use a gentle rolling technique to avoid moving seeds around. Rolling too hard or fast can push seeds out of place. If the seed is loose, drag a piece of carpet or board lightly instead. This helps press seeds without shifting them. Avoid rolling on windy days to keep seeds from blowing away.

Check the seed type and soil condition before rolling. Some seeds need less pressure to stay put. Use a lawn roller that is not too heavy for seeded areas. Proper rolling helps seeds germinate evenly and grow strong.

Credit: www.aosom.com

Frequently Asked Questions

What Can I Use In Place Of A Lawn Roller?

Use a heavy, smooth object like a water-filled drum, a weighted board, or a piece of carpet dragged over the lawn. A homemade roller from a metal drum filled with water or sand also works well. These alternatives help press grass seeds and smooth soil effectively.

How To Make A Homemade Grass Roller?

Clean a drum, drill axle holes on both ends, insert a metal rod as axle. Seal ends, add a fill hole. Fill with water or sand. Attach a handle frame for easy rolling.

What Can You Use As A Garden Roller?

Use a water or sand-filled drum, a heavy metal pipe, or a homemade barrel roller. Lightweight plastic rollers also work well.

How To Roll Grass Seed Without A Roller?

Drag a flat board, carpet, or a broom gently over the seeded area to press seeds into the soil. Avoid disturbing seeds.

Conclusion

Building your own lawn roller saves money and adds value to your yard. It’s simple with basic tools and materials. Rolling helps flatten soil and improve seed contact for better growth. Use water or sand to adjust the roller’s weight as needed.

Regular rolling keeps your lawn smooth and healthy. Give this DIY project a try and enjoy a neat, even lawn all season.